Biomass as resource – Sustainable by nature

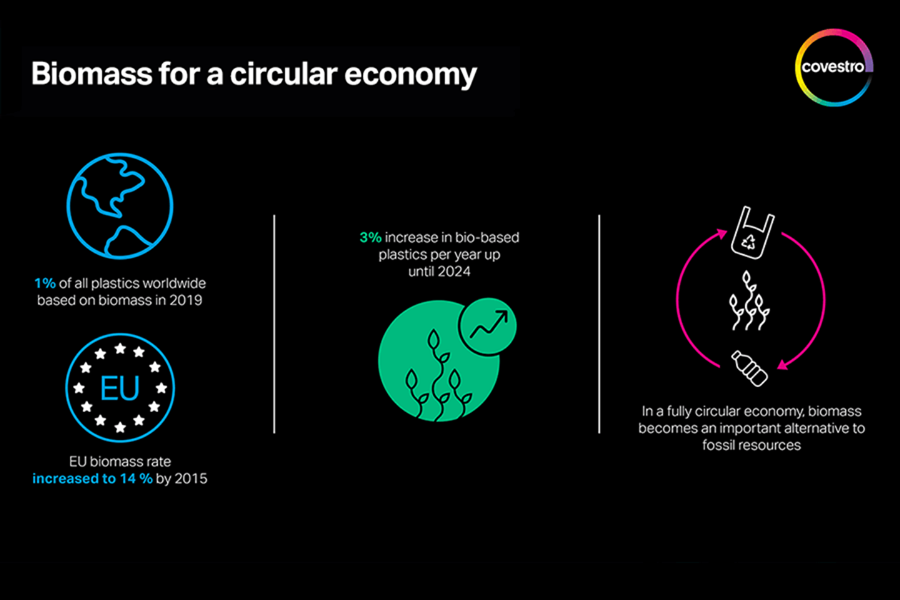

Chemicals and renewable raw materials – a combination that many may find unconvincing at first. But ideas such as producing plastic from biomass have the potential to lead us to truly sustainable solutions. Therefore, the chemicals industry is increasingly relying on renewable raw materials.

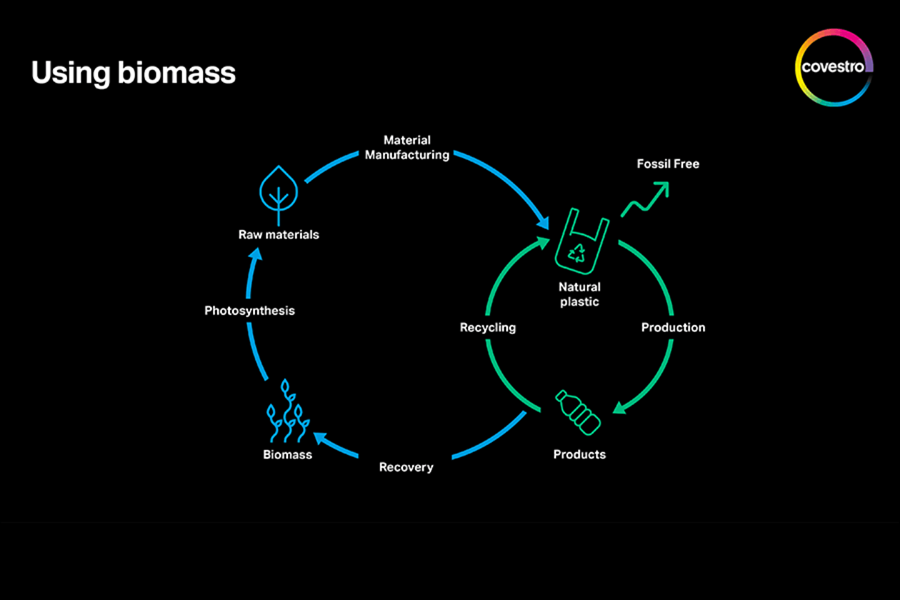

Using carbon from biomass and feeding it back into the loop – this is the path Covestro is taking to propel the circular economy. For years, the company has been using more alternative raw materials to develop and manufacture of its products, with the goal of reducing its dependence on fossil resources such as petroleum and becoming climate neutral. This has been Covestro’s response to its customers’ growing interest in relevant solutions.

Plastics from used oil and grease

The bio-based raw materials that Covestro uses come from organic waste such as used oil and grease, among other sources. They are produced by suppliers according to the mass balance method of the ISCC PLUS standard. Various manufacturers supply Covestro with suitable raw materials, including phenol and acetone for producing the high performance plastic polycarbonate, and benzol and toluol for isocyanate, which is needed for polyurethane foam.

Sustainable car coatings

Protecting and beautifying: coatings are needed in many areas of life. Covestro produces specialized components that help improve their performance, such as hardeners. Today, more and more of our coating solutions are formulated from biomass. For example, the company offers a hardener for car coatings, whose carbon content is sourced from up to 70 percent renewable raw materials – without compromising its protective function or aesthetics. In the future, biomass is also set to play a major role in formulating sustainable coatings for furniture and wood processing, reducing negative impacts on the environment.

Breakthroughs in research

Covestro and its partners have achieved an award-winning success in the field of renewable raw materials: the development and production of aniline completely from biomass. One hundred percent of the carbon in this important base chemical is obtained from industrial sugar, which is a renewable plant-based raw material.

The entirely new process, which also uses biotechnology, reduces the CO₂ footprint of aniline. Following this research breakthrough, Covestro is now working on developing the technology and implementing it on a larger scale. A special pilot plant was set up for this purpose at the Leverkusen location, making it the first of its kind in the world.

And Covestro sees even more possibilities. For example, in cooperation with the American company Genomatica, it succeeded in making the first plant-based variant of the important plastic component HMDA – again with the aid of biotechnology. A milestone for the industry. Coatings, clothing, adhesives and plastics can be manufactured in an even more sustainable way in the future.

Our overall goal is to promote the use of biomass and renewable raw materials across our industry, making chemical production fit for the future. We believe bio-based products are one important step in permanently reducing our emissions and making the chemical industry a more sustainable place.