We don't say it's easy – but possible. Together. #FullyCircular

First, the right economic conditions must be in place. However, political measures will also be needed, such as a wide-scale expansion of renewable energy technologies.

Like all companies today, Covestro is faced with the challenge of making its business operations truly sustainable. As a company that has been focused on sustainability since its founding, we want to meet this challenge with conviction and commitment. Because of this, we will continue to support and promote better sustainability. We also position our plastic production fully in line with the principles of the Circular Economy.

What drives us: achieving climate neutrality on our path to the Circular Economy

Our journey of transformation towards the Circular Economy is a comprehensive one. It includes ambitious targets for reducing the emissions generated by our own production, as well as emissions from purchased energy sources and those from our upstream and downstream supply and value chains.

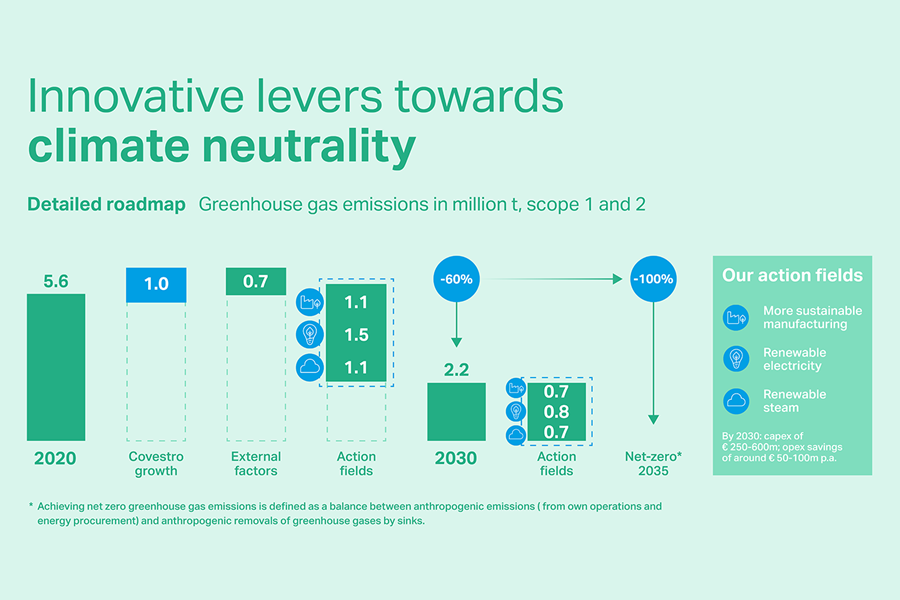

The year 2035 marks a key initial milestone on our path. Our goal is for our operations to be climate neutral by that date, with respect to emissions from our own production (scope 1) and emissions from purchased energy sources (scope 2). By introducing absolute reduction targets for scope 3 emissions, we have now significantly advanced our comprehensive climate strategy for achieving climate neutrality: we want to reduce our CO₂ emissions by 10 million tons (-30% compared to the base year of 20211) along the supply chain by 2035. That is what climate neutrality means for us.

Compared to the base year of 2020, we have already achieved a global reduction in scope 1 and scope 2 greenhouse gas emissions. We have succeeded in doing so partially by using less primary energy, and by reconditioning the catalysts that capture nitrogen oxide. We need renewable sources for power and steam. Because of this, we are advancing co-operations and concluding power purchase agreements (PPAs) with our energy suppliers worldwide.

Success along the supply chain – alongside our partners

We know that we, as a company, can only be successful if we involve our partners, customers, and suppliers right from the start.

This is particularly true for our company's scope 3 targets. Covestro published climate neutrality targets for scope 3 emissions in 2024, and in doing so took another key step on the path to transforming our company. We aim to reduce emissions from upstream and downstream processes in the value chain to net zero by 2050. In order to meet this challenge, we must act as trailblazers and develop solutions alongside our partners along the supply chain.

More sustainability in the chemical industry, step by step

We base our plans on realistic milestones, which serve as our guide to reduce our carbon footprint. We want to continue reducing the direct emissions resulting from our production, and bring indirect emissions to net zero – for instance by choosing the right energy suppliers and sources.

Our goals to achieve operational climate neutrality were an ambitious step in our climate strategy. Our goals to reduce scope 3 emissions, which are likewise both ambitious and realistic, complete our strategy for climate neutrality.

What climate neutrality means: Our scope 1 and 2 targets

Scope 1 and scope 2 emissions are defined as the emissions generated directly by a company's activities. scope 1 emissions come from Covestro's own production processes, while scope 2 emissions come from purchased energy sources. Thanks to successful improvements in our operational processes at all major production sites, we have succeeded in reducing our specific emissions by more than half between 2005 and 2021. This was incentive enough for us to define a new, even more ambitious goal in 2022: namely to become a climate-neutral company. While our greenhouse gas emissions totaled 5.6 million tons in 2020, we want to reduce this figure each year, achieving a reduction of 60 percent (to 2.2 million tons) by 2030.

Our goals in detail

To achieve our scope 1 and 2 goals, we are focusing our processes, our production and our power and heat usage even more with an eye towards sustainability, climate neutrality and energy efficiency.

Reducing our own emissions

In order to reduce our scope 1 and scope 2 emissions to net zero, we will focus on our own corporate performance and operations – by manufacturing our products in a more sustainable and energy efficient manner. For example, we are using innovative catalyst technologies in our isocyanate production to reduce CO₂ emissions. Isocyanate and diisocyanate are the most important base materials used to manufacture polyurethanes.

Reducing indirect emissions

In order to further propel our shift to more sustainable energy sources (scope 2) and supply our production sites worldwide efficiently with energy, we will build on innovative models of cooperation with energy suppliers. Towards renewable energy sources. This type of collaboration will bring us closer to net zero, and to a smaller CO₂ footprint.

Offering products in climate-neutral versions

In order to meet the growing demand for sustainable products and reduced waste, Covestro has significantly expanded its portfolio, and continues to develop climate-neutral variants of its materials. We are approaching fundamental, macroeconomic challenges with unique solutions for our target markets – in areas like mobility, construction, the furnishing industry and renewable energy, we want to deliver answers in line with the aims of the UN Sustainable Development Goals (UN SDG).

Sustainability is increasingly in demand, partially due to global developments and trends. Urbanization, for example, requires new approaches to building energy-efficient homes and modernizing existing buildings. Large quantities of MDI (methylene diphenyl diisocyanate) are used for this purpose worldwide. It is an essential raw material for applications like manufacturing polyurethane foams (PU). Covestro introduced climate-neutral MDI into its product range2 in 2022.

In the long term, we want to offer a climate-neutral version of all of our products. We use alternative raw materials and energy sources as well as unique, newly developed technologies for our CQ solutions. CQ stands for Circular Intelligence, a smarter approach to using more sustainable materials and technologies. Currently, all CQ materials consist of at least 25% alternative, non-fossil raw materials. Technologies under the CQ label, such as Evocycle® CQ, also prove that closed cycles are already possible today.

As the demand for electromobility grows, along with the promotion of electric vehicles, the associated infrastructure must keep up with new developments. When installed in charging stations, climate-neutral polycarbonates can deliver savings of up to 450 kilotons of CO₂ by 2030. Covestro has been offering such polycarbonatessince 2021.

Invest in innovation

Our goal is to continue driving the Circular Economy, while using raw materials carefully. We want to reshape the market for alternative, non-fossil-based materials alongside partners and other sustainable businesses in the future. The alternative raw materials we already use include biomass, waste products, carbon dioxide and hydrogen – we are able to make these materials useful for our purposes thanks to pioneering technologies and co-operations. This is just one of the reasons why we will be investing more and more in these kinds of innovative solutions and projects in the future.

What climate neutrality means: Our scope 3 targets

Scope 3 emissions include all greenhouse gases produced in the upstream and downstream supply chains. These emissions make up around 80 percent of Covestro's total greenhouse gas emissions. We have significantly advanced our comprehensive climate strategy by introducing absolute reduction targets for scope 3 emissions. As a short-term goal, we plan to achieve a reduction of 10 million tons of CO₂ (a drop of 30 percent compared to 2021) by 2035. We want to reduce our scope 3 greenhouse gas emissions to net zero tons of CO₂ by 2050. To achieve this goal, we are scrutinizing every part of our supply chain. A variety of interlinking factors play a key role in this process – including the availability of alternative raw materials, renewable energies, technological advancements and new processes, as well as market transformations.

Calculating scope 3 emissions is challenging for us as a chemical company. This is because such emissions are generated both when we purchase raw materials and when we sell our products. Because of this, measures to reduce scope 3 emissions impact our suppliers as well as our customers. Through innovation, co-operations with our partners along the value chain, and a detailed plan of action involving all four levers, we want to achieve our scope 3 targets.

Reducing scope 3 emissions necessitates a transformation throughout the complete value chain. Various interlinked factors – including the availability of alternative raw materials, renewable energy, technological advancements, new processes and market transformation – play crucial roles in this endeavor.

Climate neutrality for Covestro: Our goals for scope 3 in detail

We use levers in four central areas to reduce our scope 3 emissions – including through collaboration with our suppliers and through innovative products made of alternative raw materials.

Suppliers reducing their scope 1 and 2 emissions

Covestro is working actively with its suppliers to reduce their emissions, and supporting them in developing and consistently implementing concrete scope 1 and scope 2 targets, so they can become sustainable companies. By supporting reductions in scope 1 and 2 emissions by our suppliers, we in turn reduce our own scope 3 emissions. Climate-neutrality, in particular along the supply chain, is a goal we can only achieve together. In addition, Covestro is also developing a purchasing strategy for when, and in what form, strategically important raw materials can be purchased from bio-based or waste-based sources. Key bio-based and waste-based raw materials play an important role in reducing scope 3 emissions.

Profitable sales of products made of renewable raw materials

Climate neutrality is a goal that demands collaboration across the entire value chain. In addition to our suppliers, our customers also play a key role in reshaping our industry. Sustainable products are not only in demand, increasingly they are expected and a precondition for doing business. Offering mass-balanced products, for example, is important in this respect. Mass-balanced products are goods for which sustainable materials are used in the production process, and for which environmental impacts are calculated based on the total mass of the product. Customers, therefore, can reduce their CO₂ footprints and scope 3 emissions with mass-balanced drop-in materials made of recycled and bio-based products. Certification in accordance with the internationally recognized standard ISCC Plus is required in order to offer such products. Covestro's certified locations are Baytown und Newark (Ohio) (USA), Leverkusen, Dormagen, Krefeld-Uerdingen (Germany), Shanghai (China Mainland), Changhua (Taiwan), Map Ta Phut (Thailand), Niihama (Japan), Antwerp (Belgium), Waalwijk and Schoonebeek (Netherlands) and Filago (Italy).

MAKE projects

MAKE projects are innovative technology projects. The MAKE projects that reduce our Scope 3 emissions focus on alternative raw materials and recycling. These include, for instance, producing bio-based raw materials and using our own proprietary recycling technologies. Various MAKE projects reduce scope 3 emissions, such as:

- Bio-aniline: a newly developed process that allows us to manufacture the key basic chemical aniline from plants instead of crude oil.

- More sustainable HMDA: alongside biotechnology pioneer Geno (previously Genomatica), we developed the first plant-based variant of the chemical substance HMDA (hexamethylendiamine). HMDA is an important primary product used in paint and adhesive raw materials made by Covestro.

- Recycling PU mattresses: Covestro and Recticel have succeeded in chemically recycling the primary raw materials of soft polyurethane (PU) foam from mattresses. We call this recycling technology Evocycle® CQ.

Other supporting factors, like higher recycling rates, changes in logistics, and primary energy generation

Covestro is also working to reduce our scope 3 emissions through many other measures. These include, for example, continuing to develop low-carbon recycling technologies. Other developments expected in coming years, although not yet final, include increasing recycling rates in order to reduce emissions from incinerating waste, making changes to logistics, and primary energy generation. We will also improve our data management and reporting in order to reflect our reductions in scope 3 emissions in a more transparent manner, for instance by accelerating innovation processes through digital research and development and artificial intelligence.

Sustainability: It's not ‘whether’ but ‘how’

We have identified approaches for industrial development and more sustainable growth on our path to a Circular Economy. Promoting more sustainable action should be an overarching, guiding principle for the economy and for society as a whole. We are working towards solutions in our industry in order to do our part to meet this global challenge. Specifically, this means that we as a company implement forward-thinking processes that are sustainable and economical. Only when we succeed in doing so as a company can we bring out the best in Covestro.

In the long term, our declared goal is for 100 percent of our energy to come from renewable sources, and to use 100 percent alternative, sustainable raw materials. We also want to reduce the emissions resulting from processes along our supply chains. In order to utilize the full potential of this fundamental paradigm shift, we are undergoing a complete corporate transformation. This is the only way we feel we can be fit for the future – supported by a modern digitization strategy and our unique corporate culture.

Learn more about our corporate culture in the Covestro business report.

2035: an important milestone for the climate neutrality strategy

2035 will be an important year for Covestro. We aim to achieve climate neutrality in our operations for scope 1 and 2 emissions by this date. We have also set a short-term reduction target for scope 3 emissions by 2035: -10 million tons of CO₂ (-30 percent compared to the base year 20211). We see ourselves as pioneers in the chemical industry, and have linked our goals to those of the Paris Agreement – which aims to limit global warming to 1.5 degrees Celsius.

Our industry is committed to making a significant contribution to achieving climate neutrality, and establishing a sustainable, CO₂-neutral economy.

The entire plastics industry is changing, and we began helping to shape this change early on. Nevertheless, a significant portion of existing production methods is based on fossil fuels, and associated greenhouse gases. Because of this, we hope that others will follow our example and join us.

In a circular economy, we can protect the climate, nature and resources and achieve sustainable growth that respects planetary boundaries. Covestro and the chemical industry are part of the solution.

Determination to create a sustainable world

Covestro believes we are on the path to become a leading expert for sustainable materials in a climate-neutral world. Our vision accelerates this transformation – and our positive attitude is our drive.

In our TFCD report (Task Force on Climate-related Financial Disclosures), we document how we handle climate-related risks and opportunities, and how we are contributing to global developments on climate-neutrality in a transparent manner. This report is part of our comprehensive, non-financial reporting.

1 Partially compensation of growth-related emissions.

2 Climate neutrality is the result of an internal assessment of a partial product life cycle from raw material extraction (cradle) to the factory gate, also known as a cradle-to-gate assessment. The method we use to determine our ecological footprint is based on the standards ISO 14040/ISO 14044. The calculation takes into account biogenic carbon sequestration based on preliminary data from the supply chain. No compensatory measures were applied.