Competence center for high-performance films

The “hidden champion” from Bomlitz: Covestro Films GmbH has enjoyed rapid growth, with a clear upward trajectory ever since its founding in 1985. The site is part of Covestro's Specialty Films division. The division manufactures technical films used in applications like medical technology, automotive interiors, and ID documents across the globe. It is a leader in producing high-quality thermoplastic elastomer films under the trademark Platilon®. Nearly 100 employees who deliver outstanding performance each and every day at the Lower Saxony site play a major role in the company's success.

And it pays off: the Bomlitz site is the Covestro competence center in Germany for manufacturing thermoplastic elastomer films. The site houses product and application development, a technical center, production, supply chain (production planning and logistics) and purchasing. The other two German competence centers for producing high-performance films are located at the Covestro sites in Leverkusen and Dormagen (polycarbonate specialty films).

Thermoplastic polyurethane films for many industrial sectors

Platilon® TPU films are versatile materials used in various industries. These thin, flexible films are made of elastomeric polymers and exhibit an impressive combination of technical properties, making them suitable for a wide range of applications. Technical characteristics include elasticity and flexibility, high temperature resistance, chemical resistance, and waterproofness.

The elastomer films are used in applications such as breathable, waterproof membranes in outdoor clothing, sports equipment and wound dressings. Covestro Films' expertise lies in the design of multilayer films. These multilayered films combine various properties that can be individually customized to meet customer requirements. Platilon® is also used in car interiors and in the construction industry. The films can be used to protect roofs and walls from moisture and environmental influences or for repairing damaged pipelines. Covestro elastomer films are suited perfectly for such applications due to their excellent flexibility over a broad temperature range, their considerable weather resistance and high mechanical strength.

In recent years, global demand for thermoplastic polyurethane (TPU) films from the Platilon® range has further increased. Covestro has therefore once again expanded its production capacities at the site in 2023. The associated infrastructure and logistics were also expanded. This will enable Covestro to respond even faster to individual customer needs. In the future, both the development and the production of partially biobased material solutions will become an even stronger focus in Bomlitz.

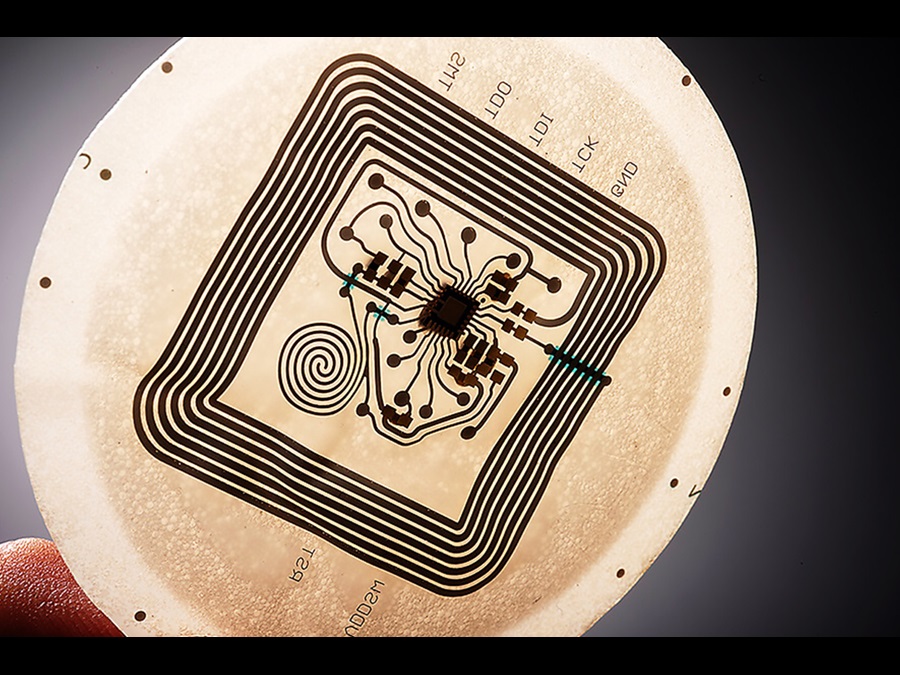

According to police crime statistics, around 65,000 documents were forged in Germany in 2022. The majority of these were personal IDs or passports. Covestro has solutions for better data protection. The company offers specialized films for integrated passport concepts that include the latest safety concepts. Covestro has developed an innovative composite film at its Bomlitz site especially suited to this purpose. It will help make documents and deeds more difficult to forge in the future. A composite film has several advantages, including being thinner than single films. This gives ID producers greater design freedom – especially when it comes to the thinner data side. As a result, security features are much easier to integrate. In addition, the composite film stands out for its excellent durability. It’s up to 35 percent more tear-resistant than the products commonly available on the market.

From smart watches to fitness tracker and digital glasses – wearables are a global trend. Wearable electronic devices are designed to make everyday life easier. Smart tools that adhere to the skin like a patch used in many medical applications – for instance, to monitor vital parameters and for patient diagnostics. Wearables need to fulfill high requirements: often, they are worn 24/7, and need to be particularly gentle on the skin while still adhering well to the body. Covestro offers the right combination of materials for lightweight, flexible and invisible skin patches that are comfortable to wear, highly breathable, soft haptics and almost invisible.

This is just one example of how Covestro Films is developing new material solutions to meet the challenges of our time. Covestro is working closely with its customers to deeply understand their needs. At the same time, the Bomlitz site continuously develops its product portfolio to meet customer needs and market requirements.

Covestro is aiming for operational climate neutrality by 2035. By then, net-zero emissions from our own production (Scope 1) and from purchased energy (Scope 2) are to be achieved. Upstream and downstream greenhouse gas emissions in the value chain (Scope 3) are also to be significantly reduced by 2035 – in the long term, Covestro aims to achieve climate neutrality for Scope 3 emissions by 2050.

Covestro – A good neighbor

Living together in harmony is very important to Covestro. This is why the company actively seeks out dialog and maintains close contacts with neighbors at its production sites.

Safety

At Covestro, safety comes first. The company is dedicated to reducing risks for our employees and neighbors and to ensuring safe production processes. Additional information is available on the Walsrode Industrial Park website.